Design & Fabrication

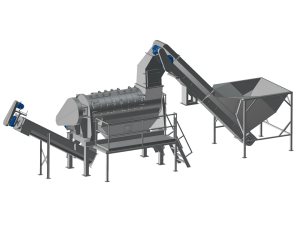

The Scott Turbo Separator was designed with a horizontal mill, as opposed to the typical vertical mill configuration used by other manufacturers. Horizontal mills allow the shaft and paddles to run at half of the RPM’s of those designed with a vertical mill. This helps the Turbo Separator operate with quiet efficiency. Systems designed by the competition macerate and chop waste packaging which leads to contamination of the organic fraction making it less desirable for end users.

The Scott Turbo Separator was designed with a horizontal mill, as opposed to the typical vertical mill configuration used by other manufacturers. Horizontal mills allow the shaft and paddles to run at half of the RPM’s of those designed with a vertical mill. This helps the Turbo Separator operate with quiet efficiency. Systems designed by the competition macerate and chop waste packaging which leads to contamination of the organic fraction making it less desirable for end users.

The Scott Turbo Separator Advantage

The Scott Turbo Separator, on the other hand, utilizes paddles that “slap” organic materials from their packaging. Gravity then causes the organics to drop through screens which delivers organic fraction that’s far cleaner and much more suitable for AD, animal nutrition, and composting. A pump/auger system offers the flexibility of handling materials that are dry, wet, or semi-solid. Water inlets offer flexibility in moisture content and can be turned off/on depending on desired end product.

The Scott Turbo Separator includes:

- Made with USA sourced steel and raw materials; built by skilled fabricators

- Stainless & Carbon steel components for extended wear and anti-corrosion characteristics and extended life span

- Pump/Auger system give the flexibility to handle wet, dry, or semi-solid materials

- Several screen sizes available for added flexibility. Easily changed for low downtime

- Standard US motors and drives. Minimal spare part required: paddles, shear bolts, screens, and belts

- Easy access to mill and drives make maintenance and repair safe and fast

For over 20 years, the Scott Turbo Separator has been the unquestioned industry leader in food waste depackaging and separation. With 4 unique models designed to handle the processing and volume needs for a variety of clients, it can handle smaller jobs like small batch separation, as well as herculean tasks found in a high-volume Materials Reclamation Facility.